The way we access and produce food is going through a constant evolution in a bid to be more efficient and cost-effective.

One area that has developed significantly in our food manufacturing is the ability to integrate up to date technology with even traditional processes.

Food technology has the power to truly overhaul our food production systems and move us into an age of almost automated farming and sustainability.

What kinds of food technology are helping our farmers and food producers?

The Internet of Things

A term that has existed 1999, the Internet of Things refers to the network of physical devices connected via wireless connections to communicate, control, update and inform the user or network about the device and its operation.

Industrial application of the Internet of Things is growing exponentially as farmers, growers and even grocers can utilise connected technologies to monitor, manage and even control everything from crop rotation to watering and feeding cycles for livestock.

Real-time analysis allows for control to a level not seen before in the food production industry.

Micro adjustments can be made all from a remote location, ‘base station’ or in some cases a smartphone or smart device.

The application is almost limitless.

By allowing for this 24-hour electronically monitored method of food production, farmers and producers can completely overhaul their running costs after an initial investment.

Process Optimisation

Whilst not technically an example of ‘technology’ per se, new developments in both computing and machinery mean that we see a constant evolution in everything from the farming vehicles to the undersoil feeding systems used to improve our crop growth.

Oil saving tech is becomingly increasing adopted alongside renewable energy sources for large-scale food production operations looking to increase productivity and energy draw potential without exponentially raising their day-to-day operating costs.

Streamlining the actual growth, feeding, packaging and shipping processes is also made possible thanks to a whole host of innovations in these key areas.

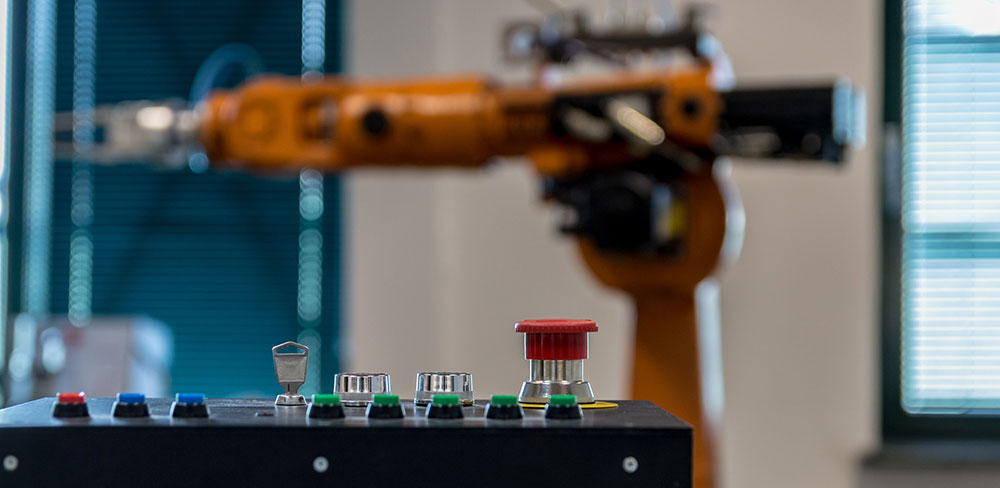

Robotics

A key area that will determine the future for a whole host of industries, robotic innovation has the potential to merge our workforce with our machinery to create a never-ending cycle of productivity using advanced AI and system management for unrivalled productivity.

Already adopted widely in the manufacturing industry, rudimentary robotic automation can take care of basic tasks and are developing the ability to perform intricate operations with accurate, consistent results that is difficult for humans to replicate.

Robots and robotics could even become the standard for intricate farming tasks, including rearing animals.

Whilst the initial costs would be high, imagine an industry where there are no real-term staffing costs, a workforce could consist of tireless machinery that is managed by a small team of engineers and service staff.

That could mean 24-hour operation, 365 days a year. A near limitless workforce.

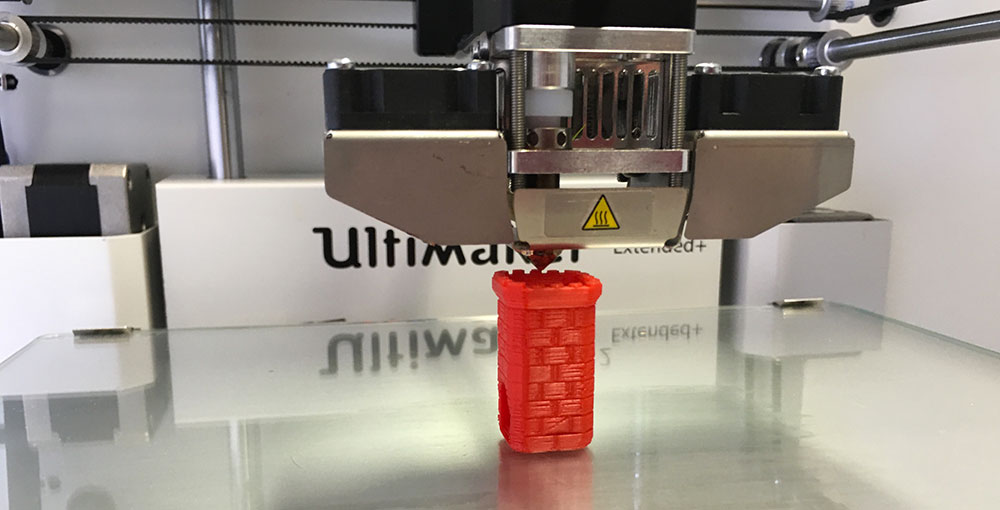

3D Printing

Conveyor belt food production is still more efficient at this point in time for almost all supermarket mass food production.

But within kitchens and especially the food production industry, we could create a range of food items that we will have never seen before.

3D printing opens up an infinite wealth of food creation opportunities that would be hard to emulate with the most traditional conveyor mass-produced food that fills our shelves, pantries and home kitchens.

The ability to literally print food means that we can make very intricate foodstuffs without the need of master chefs, bakers, confectioners and more.

We could even see the food printers find their way into the kitchen, taking the place of some staff, which although they would put certain people out of work, would save money and dramatically improve the output potential of many commercial kitchens, restaurants and more.

Enhanced usability

As we introduce more technology into the food production process, we decrease the skill threshold for some of the most intricate of tasks.

Training of a system is in most cases much easier than learning an entire process from start to finish.

Imagine turning the skilfull task of ploughing a field into a tablet-controlled remote vehicle managed automated process that only needs a few app configuration settings.

It’s actually already happening now!

We could see similar functionality and tech finding it’s way into all areas of our processes so that training goes from on-the-job to use-the-software.

Farming could become a remote process that takes place in an office rather than a field.

Higher productivity

So all of these improvements could mean that we see even higher crop outputs as longtime inefficiencies are eradicated from the system, we could potentially grow more with essentially less input.

Be that manpower, raw materials and even money.

Technology can help us do so much more than we are currently capable, and as we refine and introduce more tech into our day-to-day farming, we will most likely see gains in areas never thought possible over the past 100 years.

It’s clear that technology is going to be giving even traditional farmers some food for thought in the coming years.

As for kitchen tech, you can be sure that we will be championing some of the latest innovations so long as they benefit the professional caterer in the years to come!